Blog

-

How ePTFE Tubing Contributes to Enhanced Automotive Performance and Emissions Control

The automotive industry is in a constant state of evolution, driven by demands for greater fuel efficiency, stricter emissions standards, and enhanced vehicle performance. Engineers and designers are perpetually seeking innovative materials that can meet these challenges...Read more -

Innovations in ePTFE Tubing: Enhancing Performance of Next-Generation Implantable Medical Devices

The relentless pursuit of medical advancement is driving the development of increasingly sophisticated implantable medical devices. From life-saving cardiovascular stents to intricate neurostimulation leads and advanced drug delivery systems, these devices demand materials that offer unparalleled...Read more -

The Ultimate Guide to Selecting Chemical Resistant ePTFE Tubing for Aggressive Industrial Fluids

The Ultimate Guide to Selecting Chemical Resistant ePTFE Tubing for Aggressive Industrial Fluids In the demanding world of industrial fluid transfer, the integrity of your tubing is paramount. Handling aggressive chemicals, solvents, and acids requires materials that can...Read more -

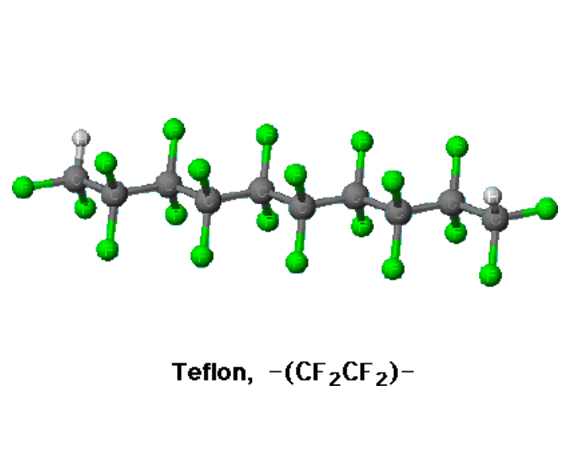

Physical properties of PTFE

PTFE is a polymer material with many unique physical properties. In this article, we will discuss the physical properties of PTFE and their importance in different applications. First, PTFE is a material with a low coefficient of friction, which makes it ideal for use as lubricants and coatings....Read more -

Where PTFE is Used? Discovering the Various Applications of PTFE in Different Industries

A Comprehensive Overview of PTFE and Its Versatility in Modern-Day Applications Polytetrafluoroethylene (PTFE) is a synthetic polymer that has gained popularity in various industries due to its exceptional chemical resistance and non-s...Read more -

Five factors to consider when selecting a PTFE coating mandrel

Over the years, PTFE coating options have grown in the medical device market, improving production processes in many different ways. And with so many materials and coating options available today, choosing the right coated mandrel for your unique manufacturing needs can ...Read more